Our Mission: Revolutionizing warehouse efficiency

Between 2019 and 2022, the challenge of identifying inventory issues in massive warehouses, sprawling over a million square feet, compelled us to seek a game-changing solution. We envisioned a future where human intervention in inventory audits would be minimized, optimizing efficiency and precision.

Navigating the challenges

In pursuit of our vision, we transitioned from a drone pilot to stationary drones on a nest. Yet, the results fell short of expectations as it failed to align with inventory audit workflows. Undeterred, we knew we had to reimagine our approach and push the boundaries further.

Unforeseen hurdles in product adoption

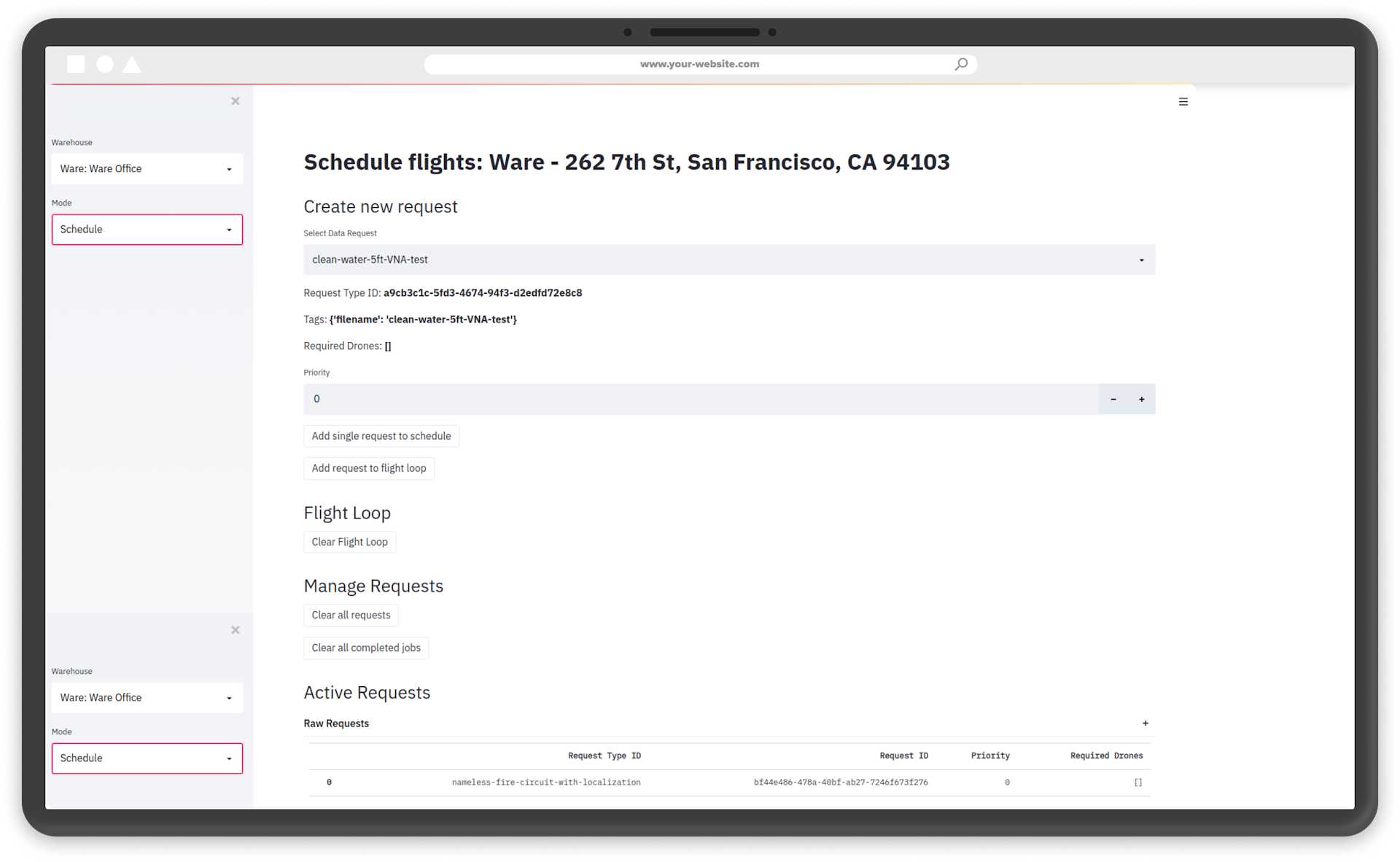

Originally meant for internal engineering, the flight planning solution unexpectedly evolved to cater to end-users. I led a comprehensive redesign, creating an intuitive interface from scratch. The result streamlined inventory audits with self-flying drones and maximized efficiency.

The image above offers a glimpse into the interface of the old flight planning web app. As you can see, the interface appears cluttered and overly complex, which posed challenges for users trying to navigate it effectively. The design heavily relied on referencing numerous location numbers, often demanding memorization from users. This complexity hindered the user experience, making it difficult for users to efficiently interact with the application.

My role at Ware

As the sole designer and a member of the engineering team, I took charge of the entire application's design, including the creation of the autonomous auditing solution from scratch. Working closely with the CTO, stakeholders, and engineers, I collaborated extensively throughout the development process.

Part of the team in a our San Francisco small warehouse. Where we would test solutions with drones.

The challenge: Automating inventory audits

We aimed to:

- Simplify flight request

- Empower users to target specific locations with ease

- An inventory audit solution that aligns with audit workflow.

Hypothesis: Our solution aimed to empower users to effortlessly select locations through the Ware portal, enabling them to create flights and await the drone's data collection to review any potential inventory issues.

Kickoff: Embracing the challenge

As the sole designer my journey began with an ambitious vision—to revolutionize warehouse efficiency using self-flying drones.

Unclear requirements and goals emerged at the project's inception, leading to uncertainty about the end-user, customer, and solution. To address this, I engaged in collaborative stakeholder interviews, gaining valuable insights into user pain points, inventory audit workflows, and business goals.

Early insights: Stakeholder interviews

Through stakeholder conversations, I gained insights into user pain points, inventory audit workflows, and business goals. Fragmented knowledge about inventory audits persisted, but valuable insights on customers, end-users, and product adoption emerged. This allowed me to create a qualitative pool of questions for five end-users.

A few insights:

Inventory control manager(user): Handles issues detected via our web portal(Ware Cloud). VP of operations(customer): Handles issues in the Ware portal.

Specified autonomous location scan rate would be slower

The autonomous drone solution would have a much slower scan rate compared to the pilot based solution. Customers were using locations scanned per hour as part of their ROI equation.

To the left is the drone trajectory of specified locations vs the right a traditional data capture all adjace nt inventory items. As you can see it would be much slower to capture locations that are far apart.

Human in the loop inventory audit workflow

Warehouse locations were physically verified against their inventory system.

Open question: It was unclear from stakeholders information on how and why specific locations were chosen for auditing.

User interviews: Revealing inventory audit insights

I conducted qualitative user research to understand inventory location auditing. I interviewed 5 inventory control managers (end-users) to delve into flight planning, audit workflows, and issue resolution on the web portal. I spent time with customers to comprehend the adoption of the POC product due to a lack of customer needs data.

User interview high level questions:

- What is the audit workflow?

- How are audit locations determined?

- Who conducts the audits?

- How and when are flights setup, and are there airspace limitations?

- How are they currently solving inventory issues on the Ware cloud portal?

Conducting research and insights

During the interviews I collected notes based on the initial question list and then synthesize the information across users.

Business problem:

Customer success was measured by labor savings, associated with locations captured by a drone. With the new data capture model and slower scan rate of autonomous drones, the conventional method became inadequate. We needed a way to shift users to measuring actual issues detected, addressing evolving dynamics.

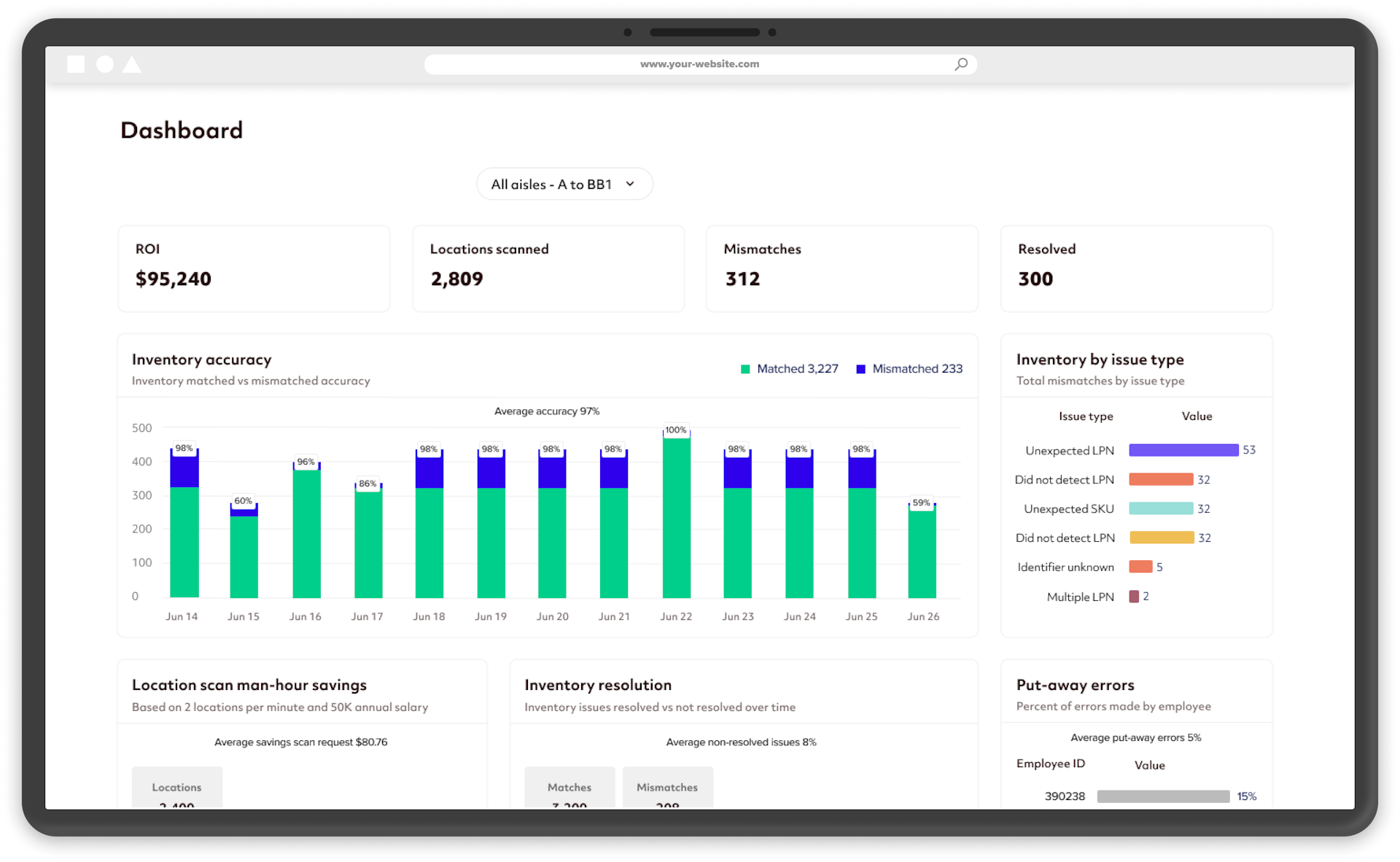

The metrics dashboard was something we worked on a few months after releasing inventory audits.

As shown in the image above, our dashboard design provides a clear view of key metrics related to labor savings and inventory discrepancies. This enabled our users to monitor and measure the actual impact of our autonomous inventory tracking solution.

Covid created a major issue, inventory auditors were difficult to hire and they had a high turnover, making it very challenging to meet guidelines on how many locations should be audited over time.

Primary user pain points:

Generating flights via our portal was difficult and had limitations. The flight planning only allowed the selection of aisles instead of individual locations. It did not mirror their audit workflow.

The inventory issues detected were aggregated on our web portal and the user was not able to segment audit results.

Useful insights:

Location audits were based on a product that was low in inventory, new employees as they were more prone to errors, random audits and the shift before locations that had inventory move.

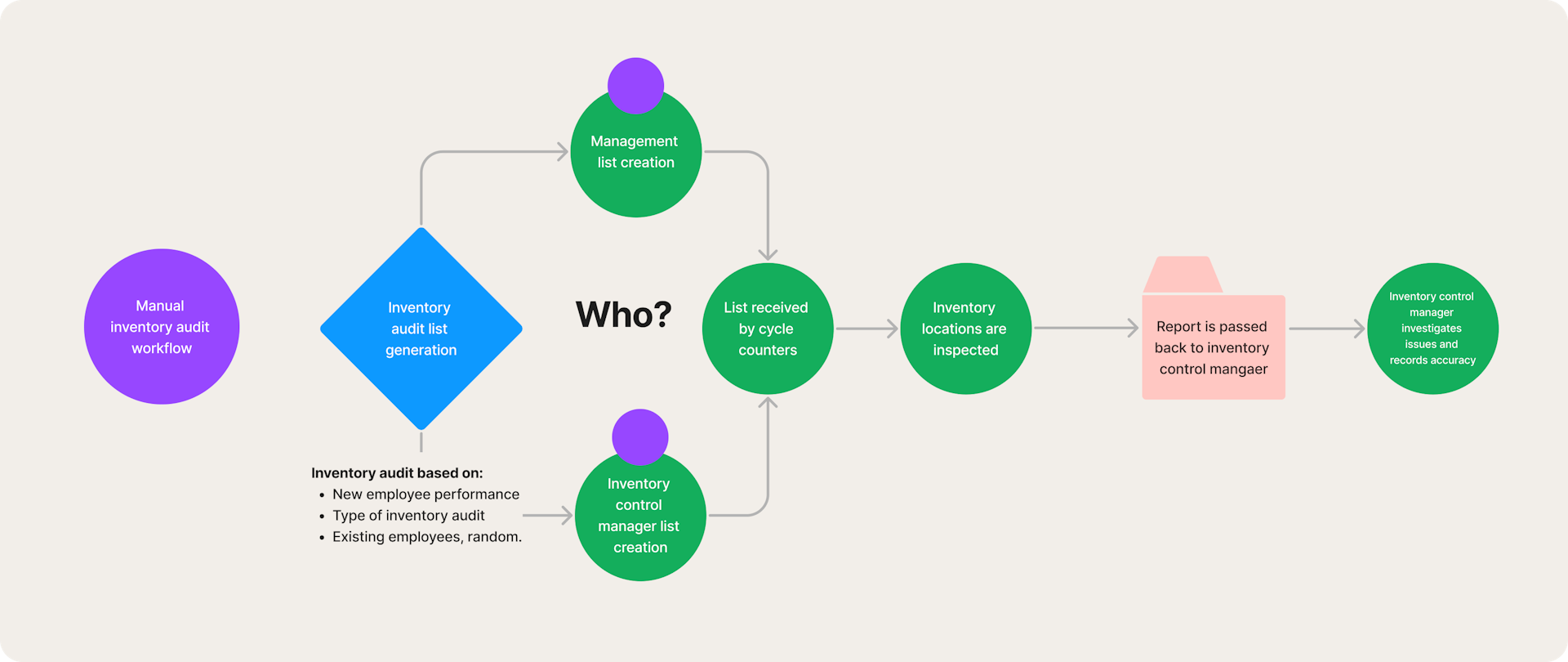

Manual inventory control workflow example:

A diagram exemplifying the manual workflow of most warehouse audits done by humans in the loop.

The hypothesis solution was not ideal:

Users did not want to select from a list of locations. Selecting a large a mount of locations manually would increase their workload. They wanted a way to quickly provide all the locations.

An example of how a user would need to manually select each audit location and how it would increase their work load.

Exploration: How might we...

- Audit specific locations with minimal effort from the user?

- Allow user to easily track all drone flights in progress and completed

- Allow users to review data when a mission composed of multiple flights to review issues to be more productive

- Allow users to segment information on a per audit basis

- Allow users to continue a mission or cancel it.

- Allow users to further automate inventory tracking.

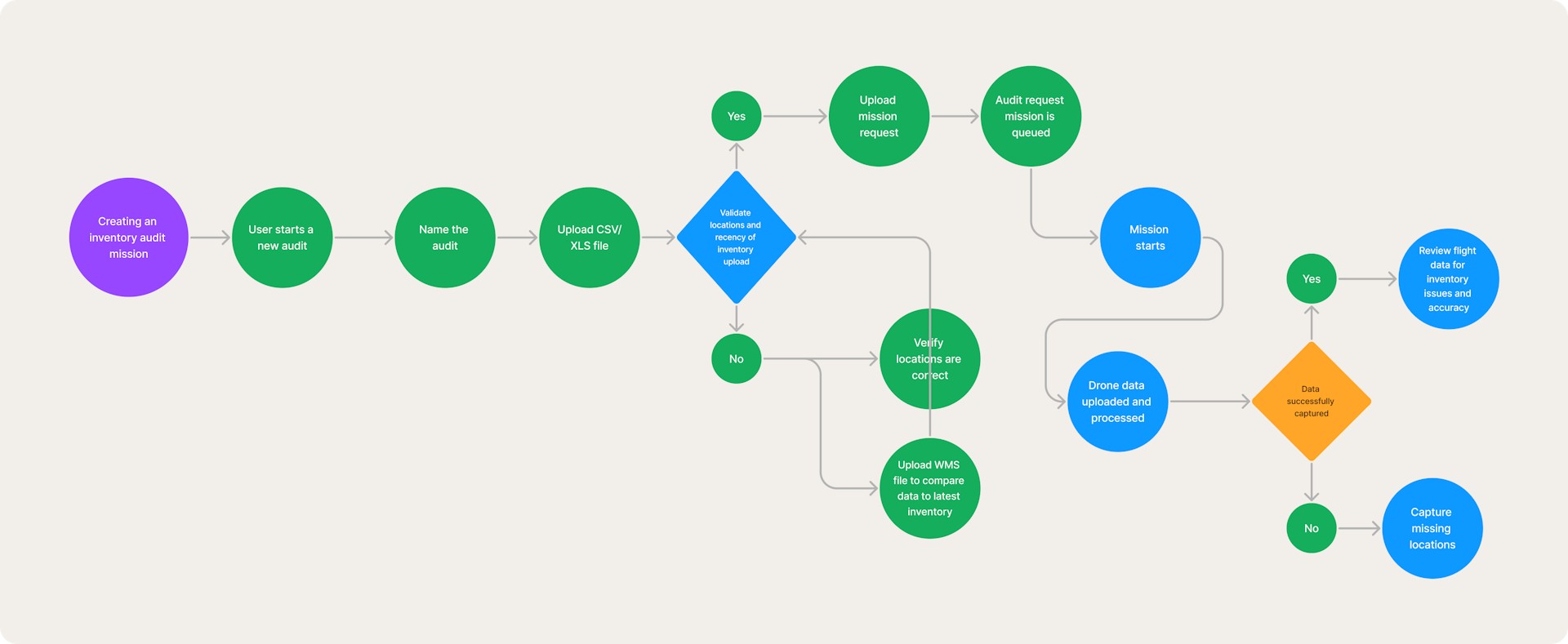

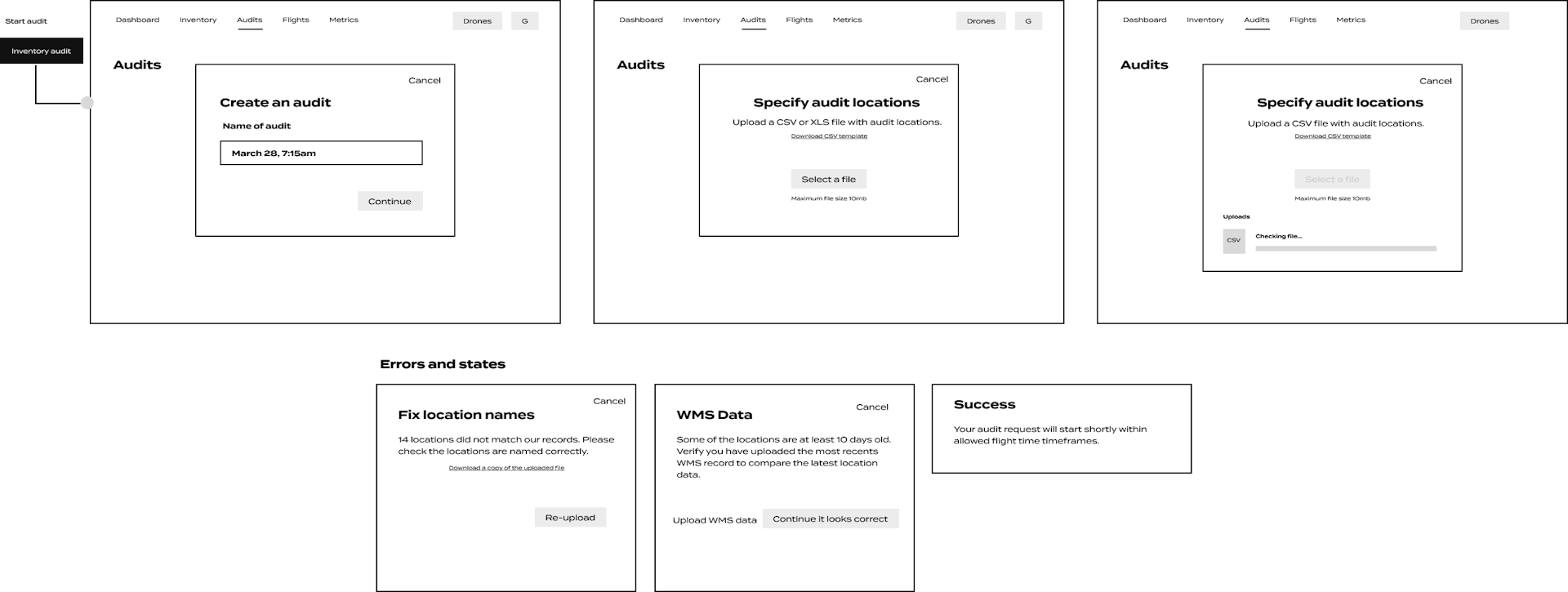

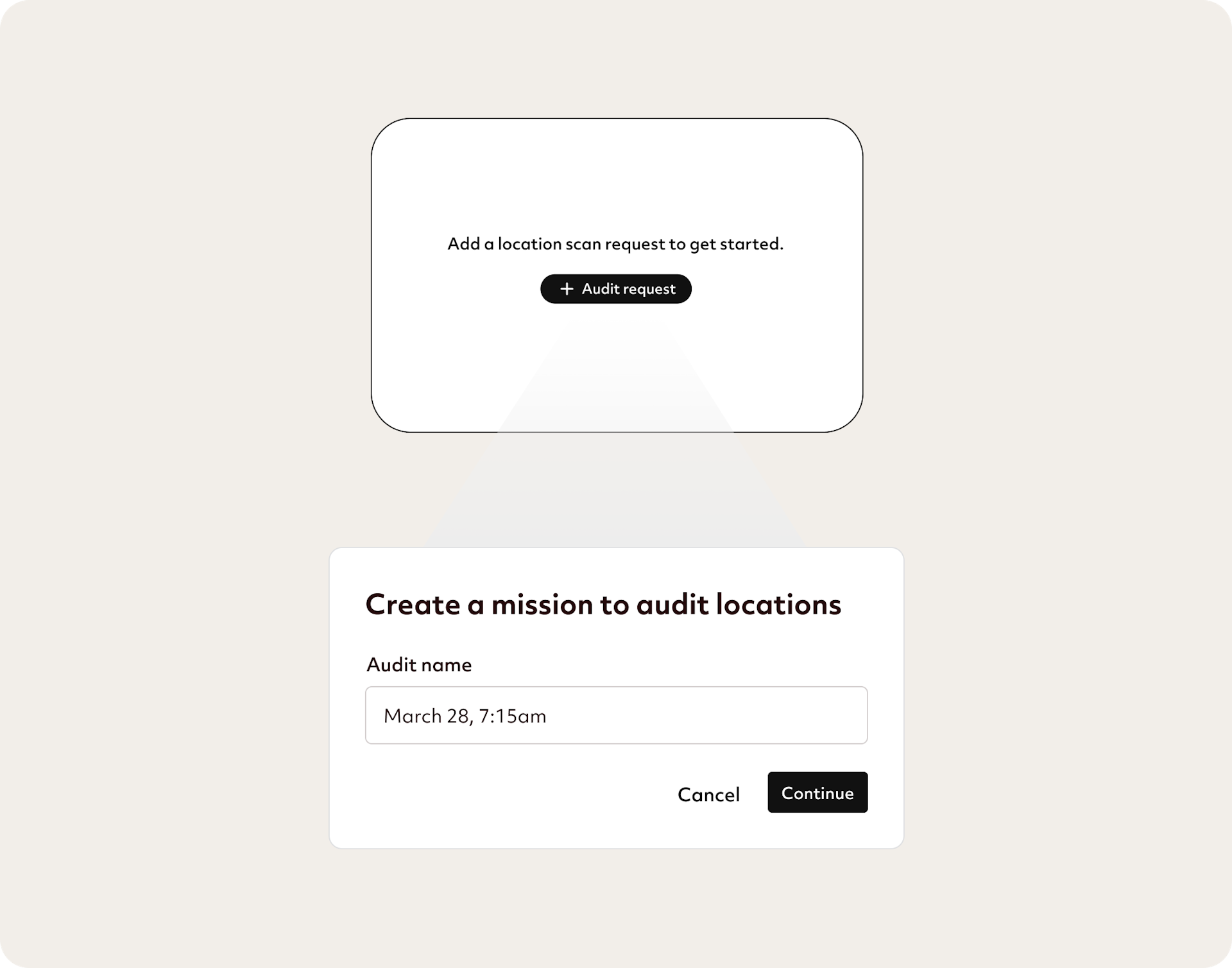

Allowing users to setup an inventory audit

At this point we explored a couple of options to allow users to quickly create flights with numerous locations.

Option 1: All warehouses generated an XLS with location.

The interface provided options to upload XLS/CSV files with existing locations or filter data based on inventory movement, product type, or employee. This approach ensured that the flight planning system closely mirrored their audit workflows and addressed their specific pain points. We also already had an upload workflow for inventory updates that could easily be re-utilized.

In the diagram we illustrate how the user would quickly upload a spreadsheet with set locations. Since the user already works off a spreadsheet it would be easy to upload and then review the audit results.

A wireframe showing part of the uploading a CSV/XLS workflow.

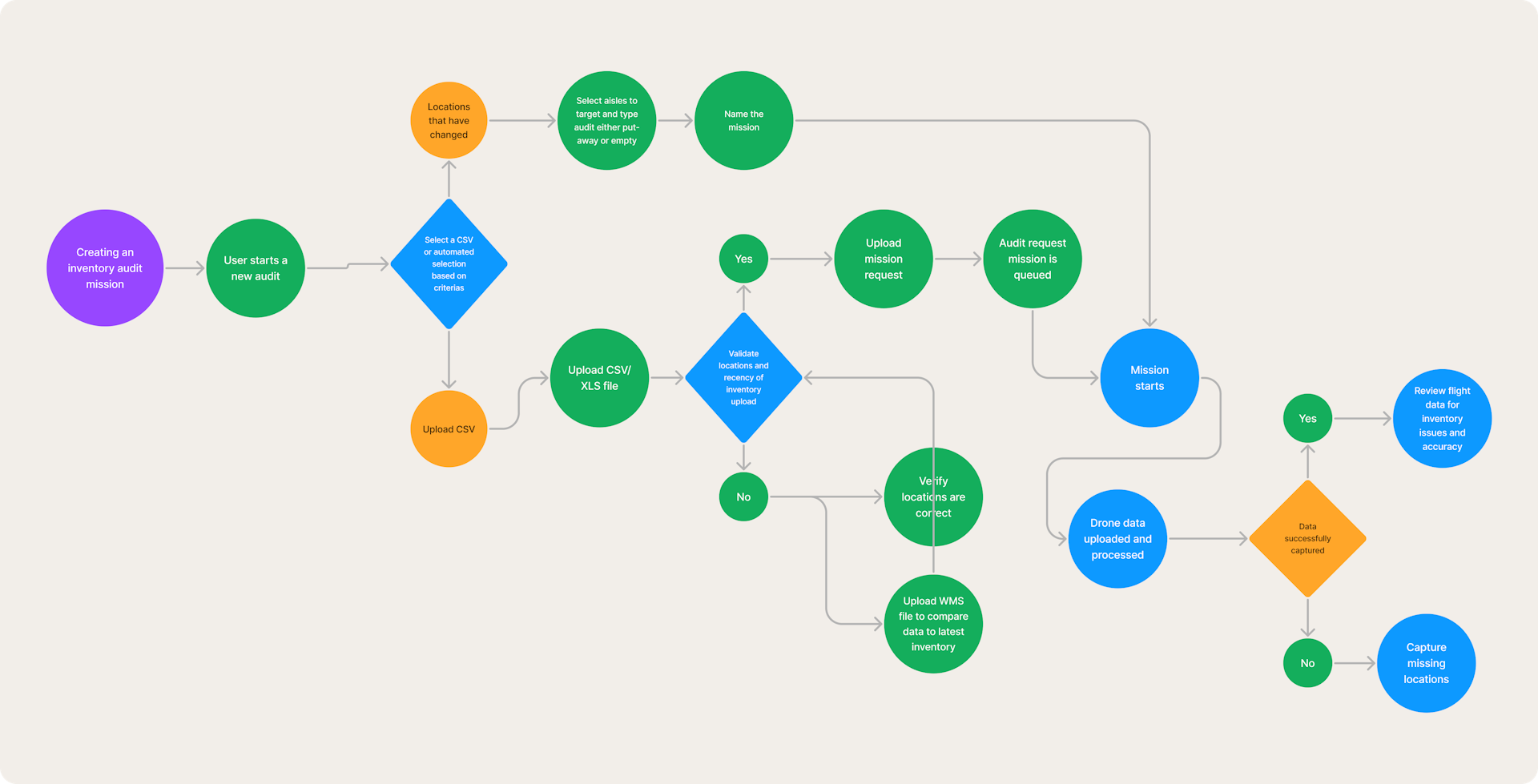

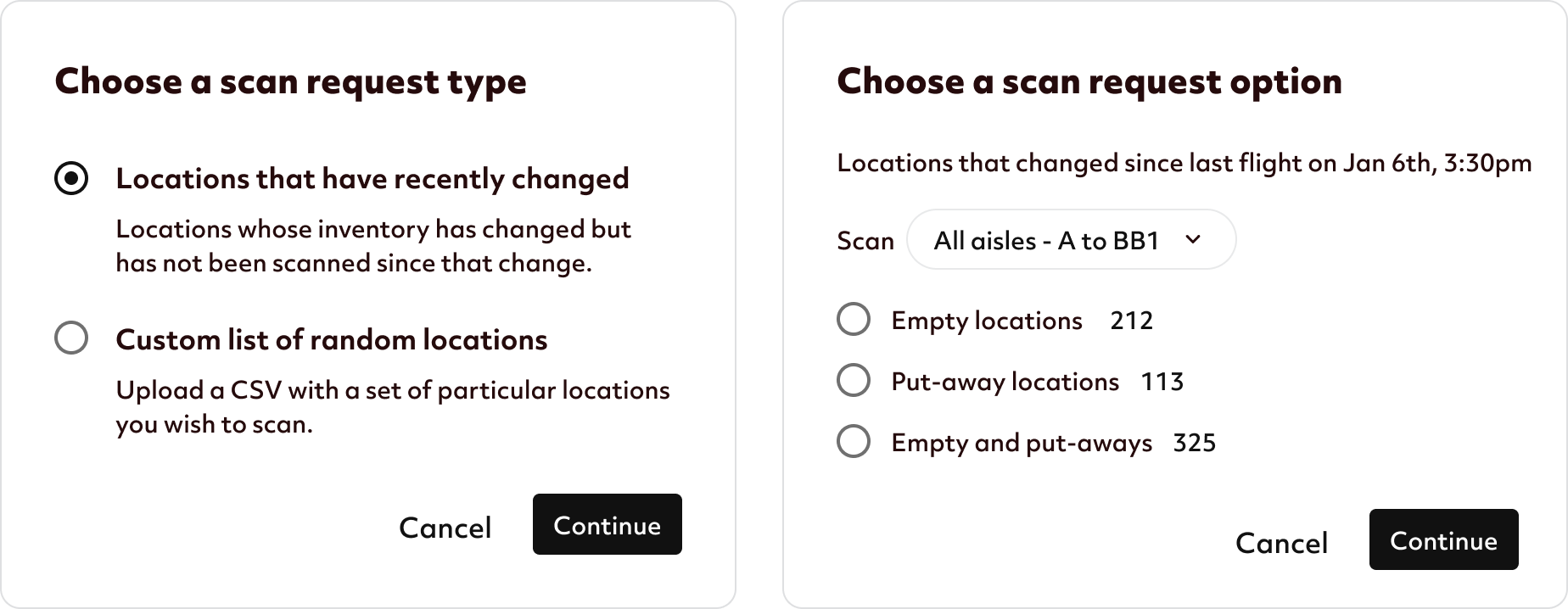

Option 2: Getting closer to an autonomous solution

The alternate approach involved enabling users to effortlessly initiate audits based on inventory movements, a critical use case that brought us closer to an autonomous solution, eliminating the need for spreadsheets or manual reports. This approach could also extend to employees and products with low inventory. The foundation for this concept emerged from our deeper understanding of the rationale behind selecting specific locations for audits.

The user flow illustrates an additional option to automatically allow the system to create a mission based on filtering by locations that had changed within the last mission.

An example of how the user would be able to easily select locations where inventory was moved instead of using an XLS.

Tradeoffs and compromises

After reviewing the upload solution and adding an additional flow to select specific locations, it was quickly determined that it would be too expensive from an engineering standpoint to go with option two. We wanted to release a quick solution and get some Beta testers.

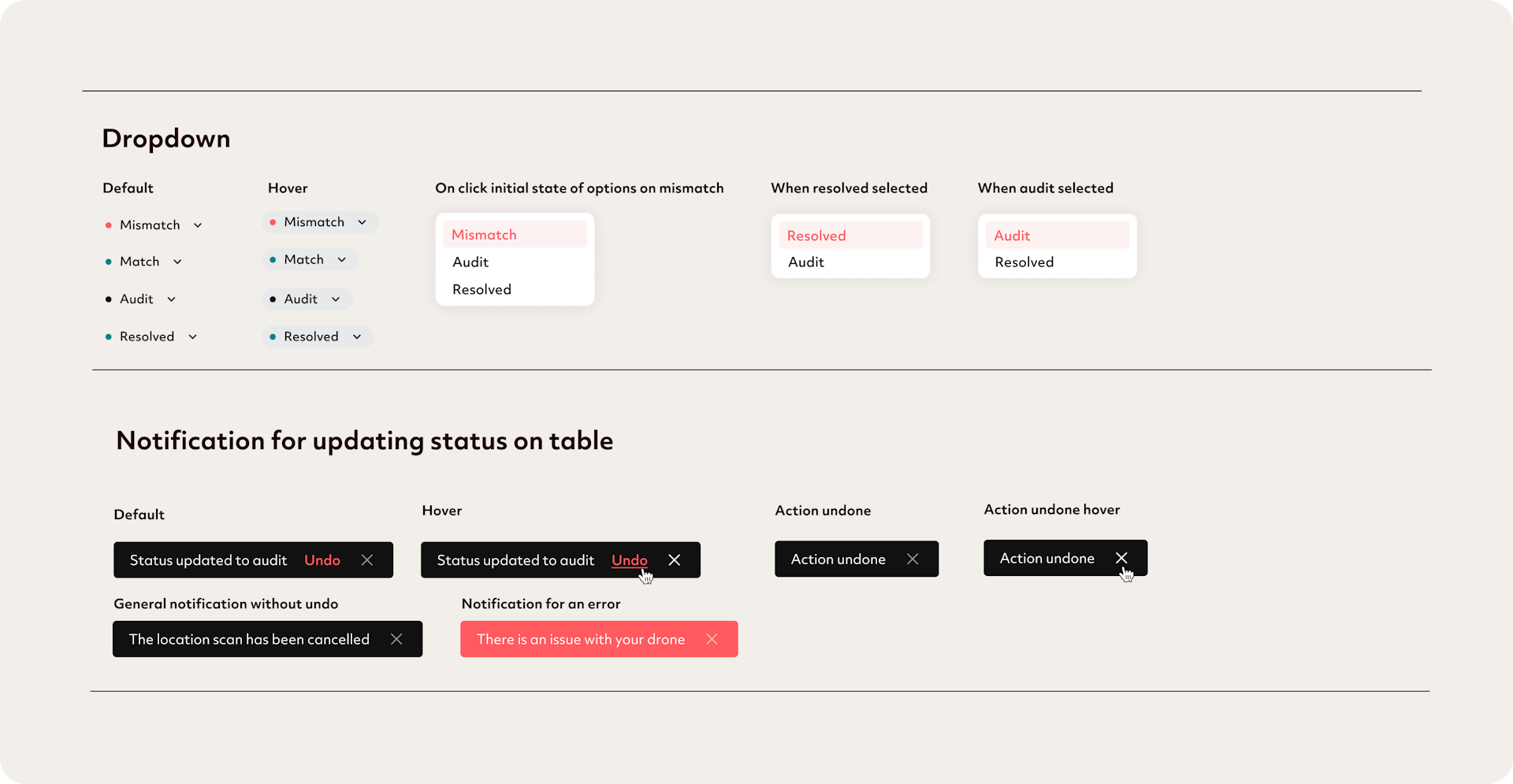

Introducing the design system

Recognizing the need for a robust design system, we established a clear set of design principles, components, and guidelines. This streamlined our design process, facilitated collaboration, and ensured a cohesive visual language.

A few components of the design system that I created in Figma from elements to components.

Creating an inventory audit

As previously explained, users needed to create an audit and upload a CSV/XLS with specific inventory locations.

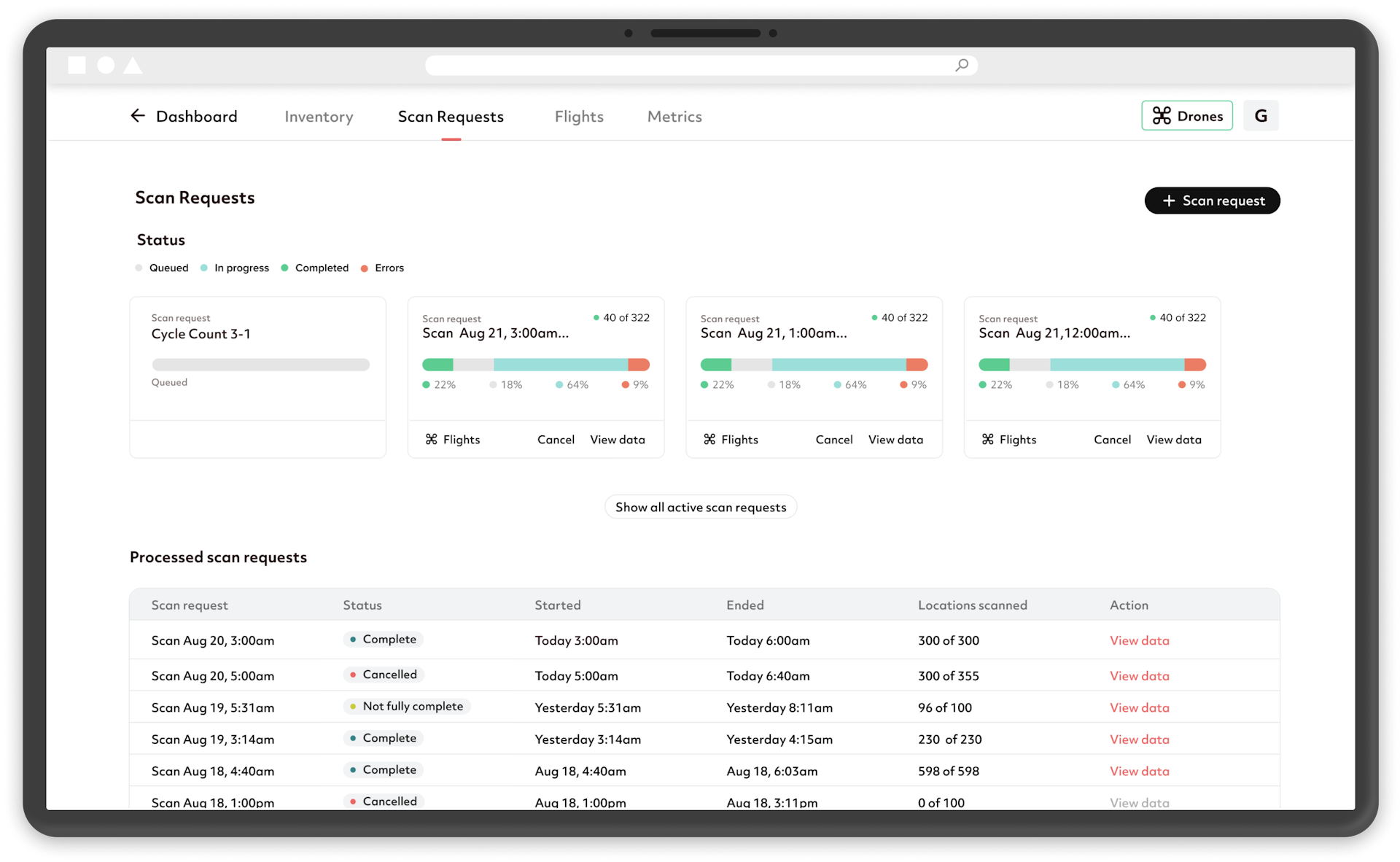

Monitor missions

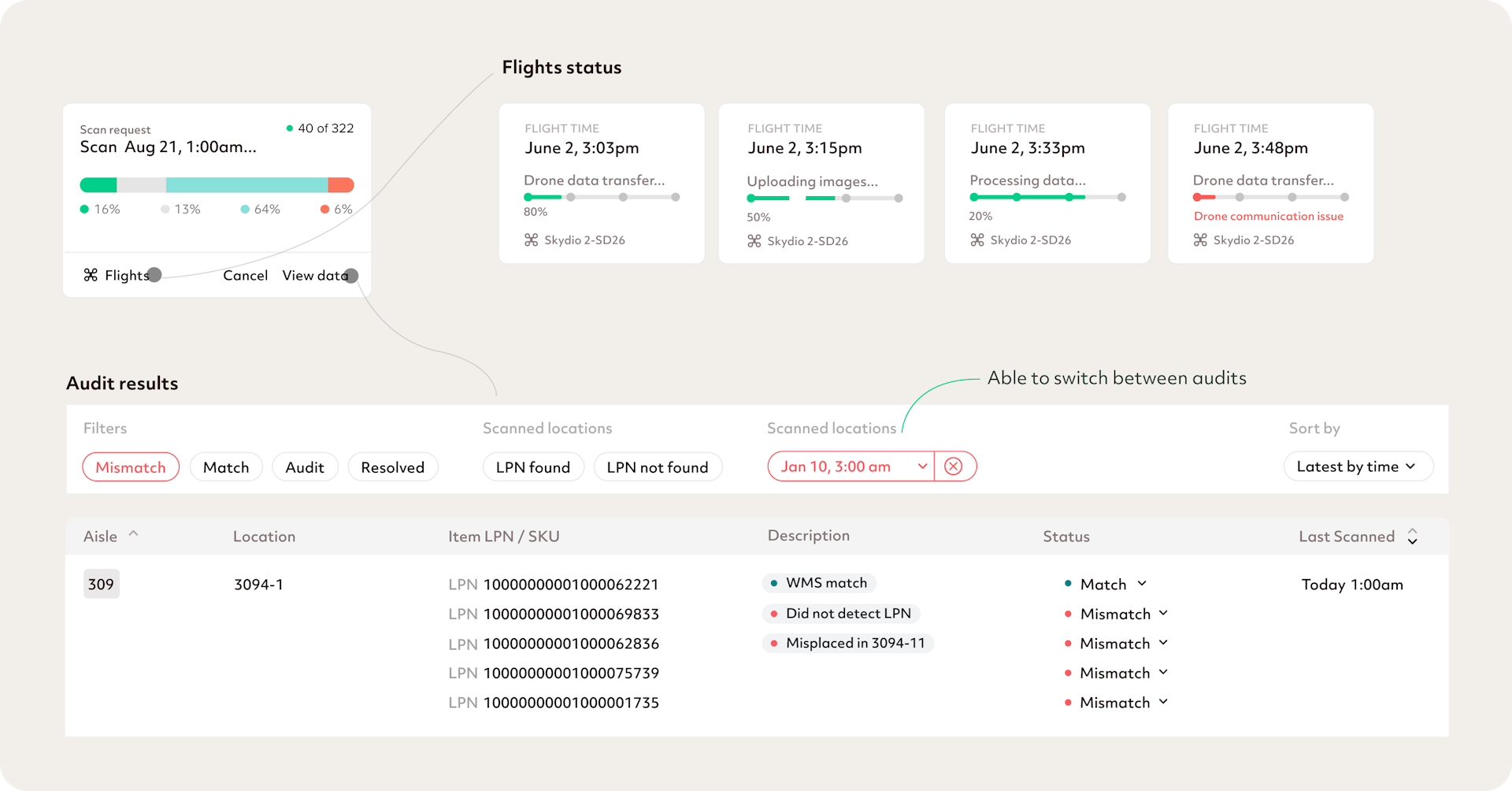

Users needed to monitor a mission and access data as it became available to be efficient, especially for warehouses with limited airspace time.

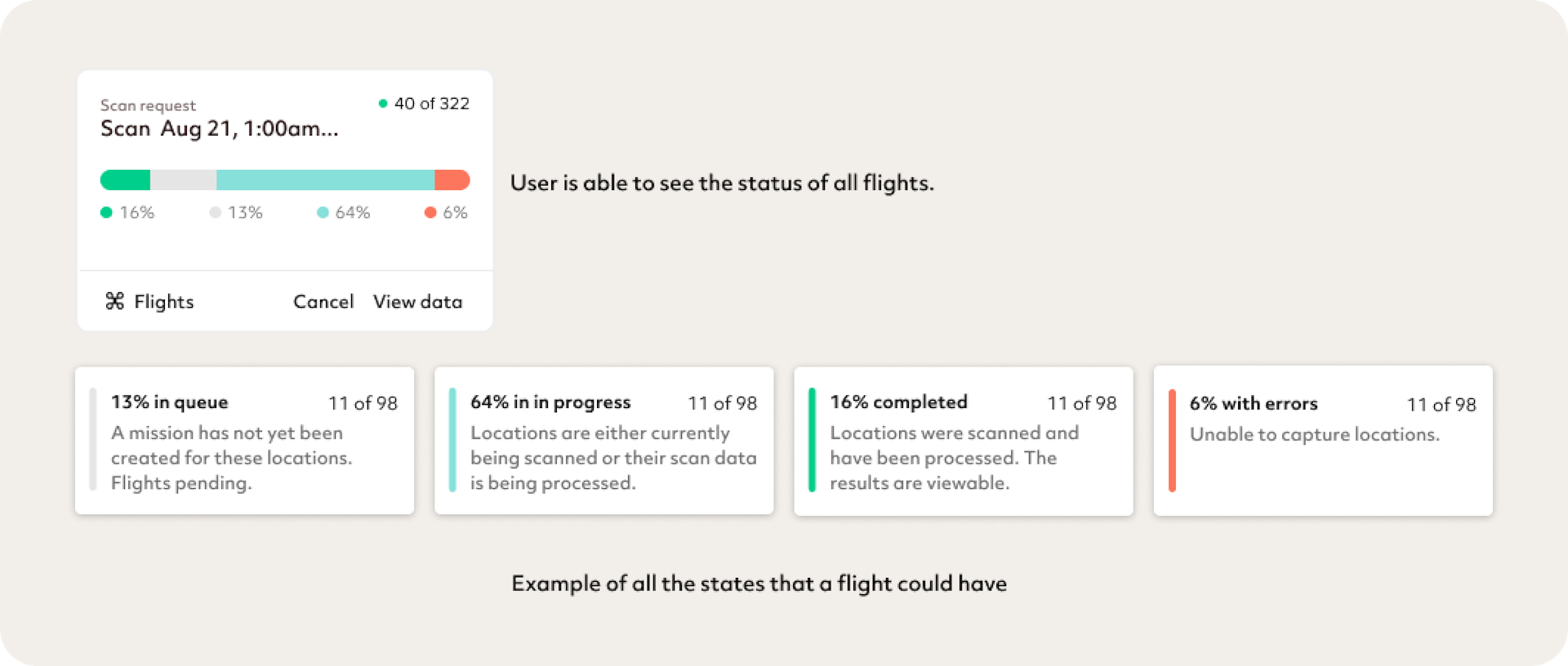

Users needed to clearly understand the state of the mission(inventory audit) at all times. The user was able to easily get an idea of completion so they could plan ahead when they would review the inventory issues on the web portal. The user was also able to see the data as the flights completed.

Image of all the states an inventory audit mission could have.

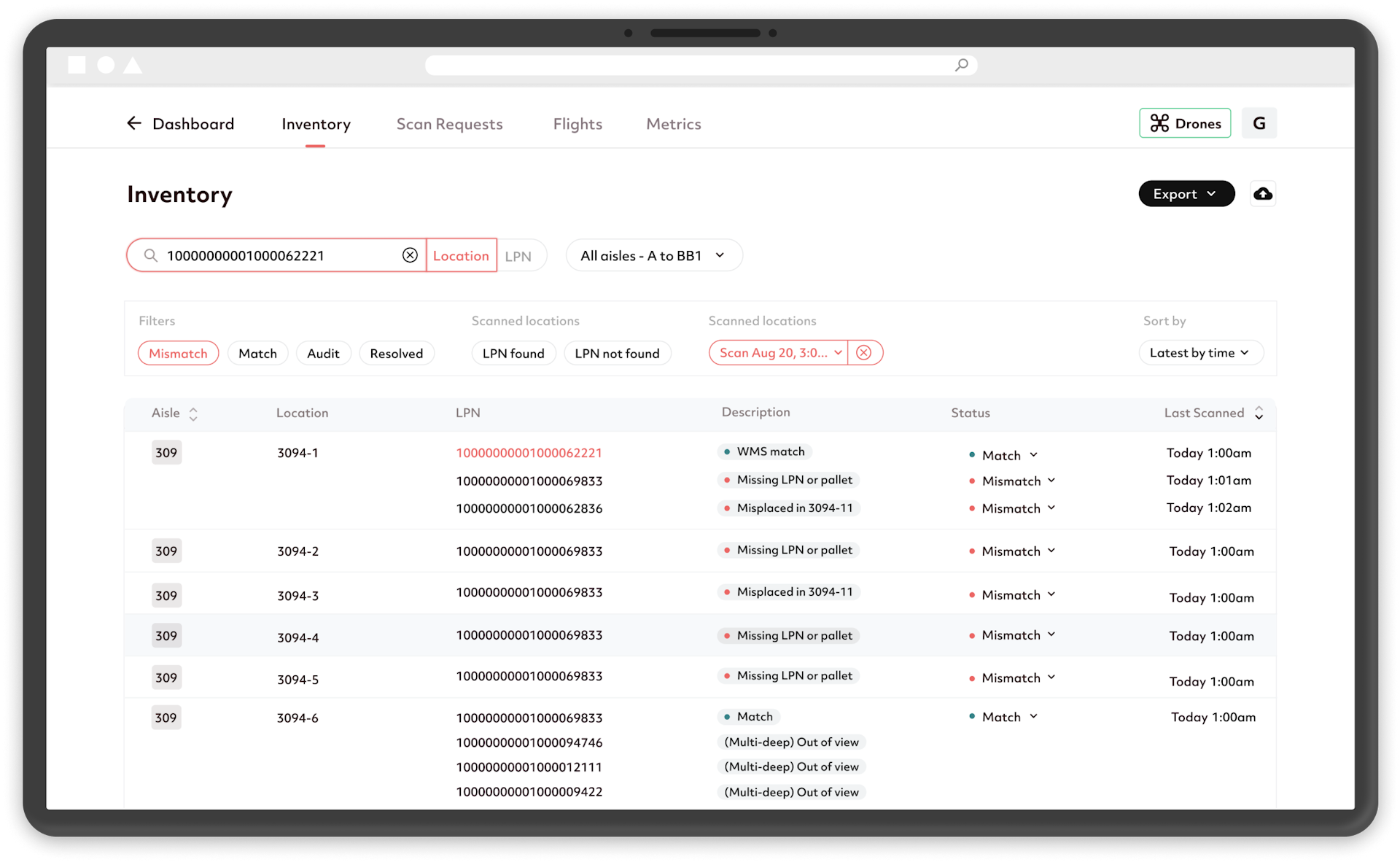

Users needed a way to easily see each audit independently within the inventory view. The primary use of the inventory view was to review any issues identified by the drone and further investigate and view inventory locations remotely. A filter was added to quickly change between audit and review results.

The visual representation above illustrates the navigation pathway for accessing data and monitoring the status of flights linked to an ongoing audit.

The image above is where the user would quickly find any issues with their inventory after an inventory audit flight is completed and ready to review. We allow the user to easily find any mismatches and remotely inspect them, providing information about the type of issue detected with each specific location to further assist in the assessment.

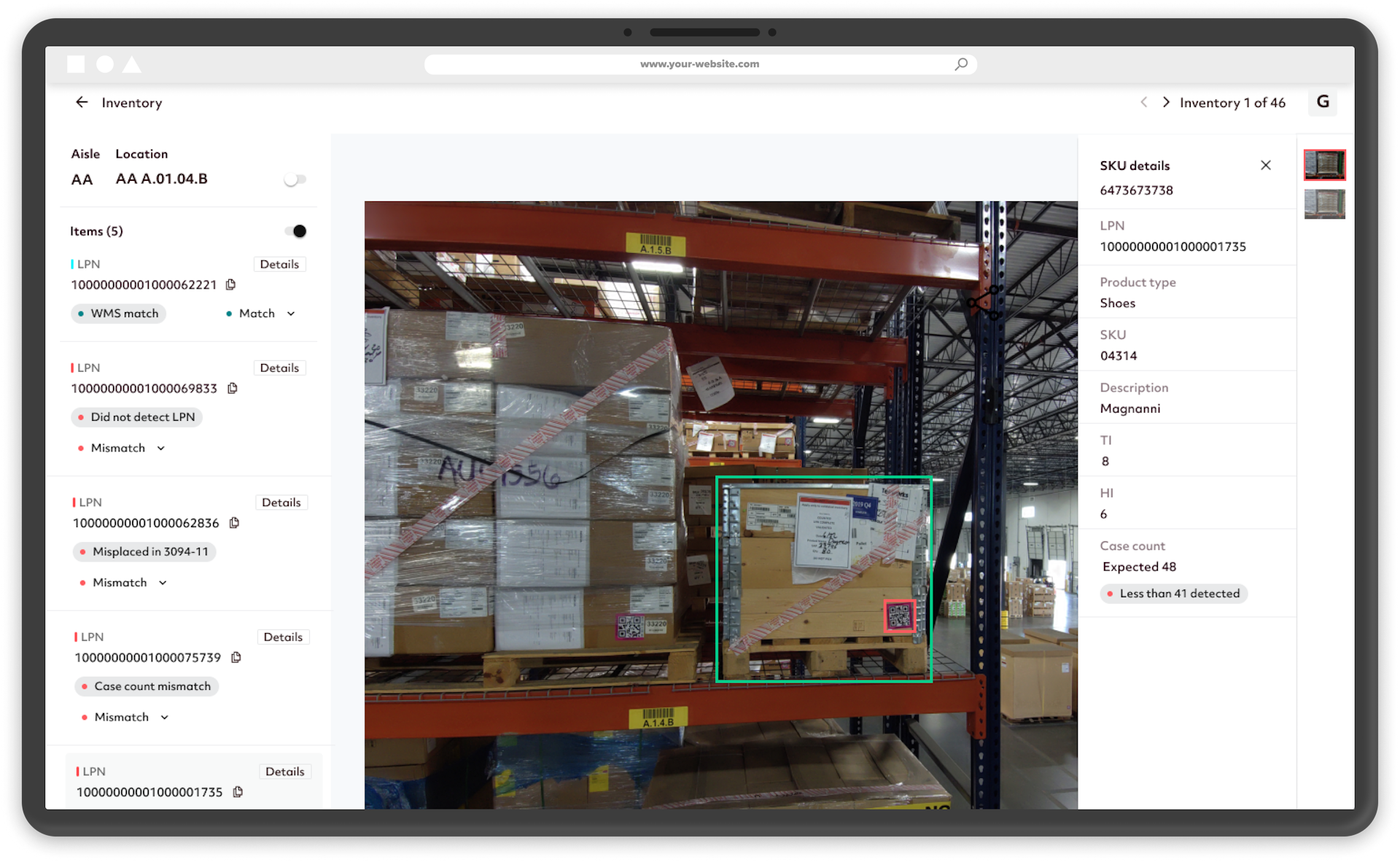

Inventory remote inspections

Users could navigate to inventory locations and inspect remotely to investigate and solve inventory issues.

The provided illustration depicts the user interface seen during the inspection of locations with detected issues, alongside their associated pallets. On the right side, an agnostic data reference is displayed, facilitating a clearer understanding of the identified issue.

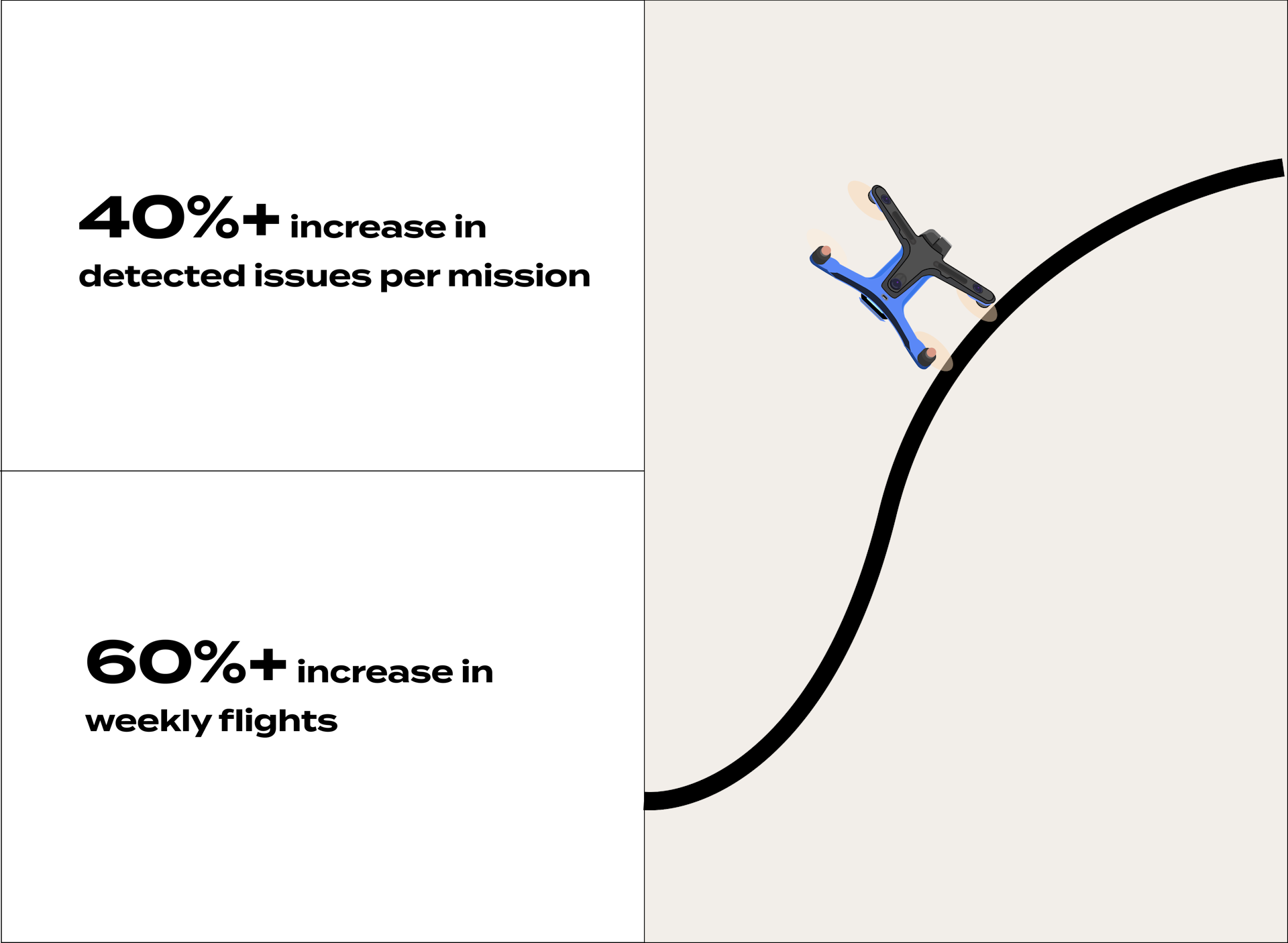

Results

The automated inventory tracking solution utilizing self-flying drones significantly improved inventory audits. The design allowed efficient audit planning, reduced manual labor, and increased control over audit locations. The new system improved productivity for inventory control managers and customers. This case study demonstrated value through user research, iterative design, and data-driven decision-making, streamlining audits for enhanced customer satisfaction.

Ware was acquired by Gather AI

Designed autonomous inventory control solution for warehouses to increase safety, productivity and inventory storage accuracy. Designed web portal from 0 to 1 to schedule drone flights and remotely inspect inventory. Lead product strategy and roadmapping. Increased product usage by 60% and helped reach 1.2M ARR within a year. Ware was acquired by Gather AI in 2023.

Key insights and lessons learned

Our journey toward redefining warehouse efficiency brought lessons. We addressed reliability, learned precision planning's importance, and achieved 100% data capture by introducing a "finish mission" feature. Progress isn't linear, but challenges become opportunities, shaping a resilient, efficient solution.

Next steps

With the project in motion, we launched a beta version to gather insights. We enhanced mission completion, monitored usage via Mixpanel, focusing on boosting the pivotal North Star metric of usage.